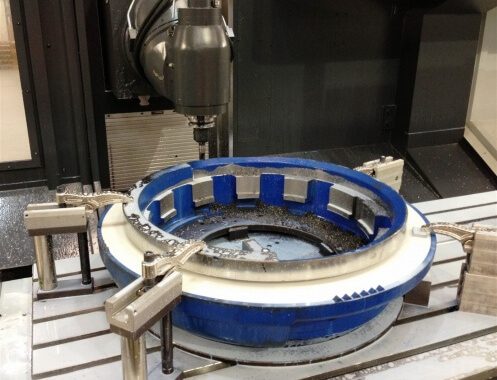

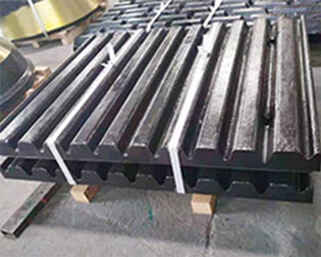

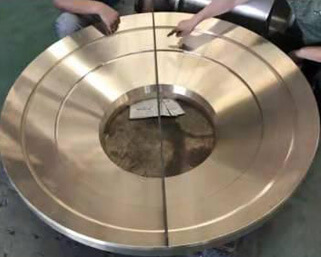

Jumborax holds stock on most common crusher spare parts; providing superior quality engineered replacement spares when you need them. We supply replacement parts for Metso, Symons Nordberg, Sandvik & Allis Chalmers crushers; some of which includes (but not limited to): Adjustment Cap, Adjustment Ring, Arm Guard, Bowl, Clamping Cylinder, Counter Weight, Counter Shaft, Counter Shaft Box, Counter Shaft Box Bushing, Countershaft Pinion, Counterweight Guard & Cover, Eccentric, Eccentric Bushing, Feed Hopper, Feed Plate, Gear, Head Ball, Hydraulic Drive Unit, Locking Bolt, Lower Head Bushing, Main Frame, Main Frame Liner, Main Frame Pin & Bushing, Main Frame Seat Liner, Socket, Socket Liner, T-Seal, Thrust Bearing, Thrust Washer, Torch Ring, Tramp Release Cylinder, U-Seal, Upper Head Bushing, Arm Liner, Bottom Shell Bushing, Bottomshell, Clamp Plate, Concave Ring, Counter Shaft Pinion, Dust Collar, Dust Seal Ring, Eccentric Wear Plate, Head Center, Head Nut, Mainshaft, Mainshaft Step, Mantle, Pinionshaft, Pinionshaft Bearing, Pinionshaft Housing, Pinionshaft Oil Seal, Piston Wear Plate, Scraper Ring, Spider Arm Shield, Spider Bushing, Spider Cap, Spyder Oil Seal, Step Washer, Toshell;

OEM Brand names have been used for reference purposes only, and are not products or brands marketed by Jumborax;